Drywite is celebrating 90 years in business, continuing a proud family tradition of producing and supplying top quality fish and chip shop essentials

When Malcolm Lee left school in 1932, aged just 14, for a part-time job as a potato boy in his local fish and chip shop, he had no idea about the foundations he was laying down.

Delighted one day at the prospect of taking home some peeled potatoes and saving his mother the chore of peeling them herself, Malcolm persuaded his father, Harold George Lee, to help him set up a peeled potato business, which in 1933 became known as the Pioneer Potato Company.

Just the start

This was just the start of the family business. To overcome the problem of their peeled potatoes turning brown when not in water, Malcolm enrolled on a chemistry course. This enabled him and his father to formulate their own preservative to keep potatoes dry and white when packed in paper bags.

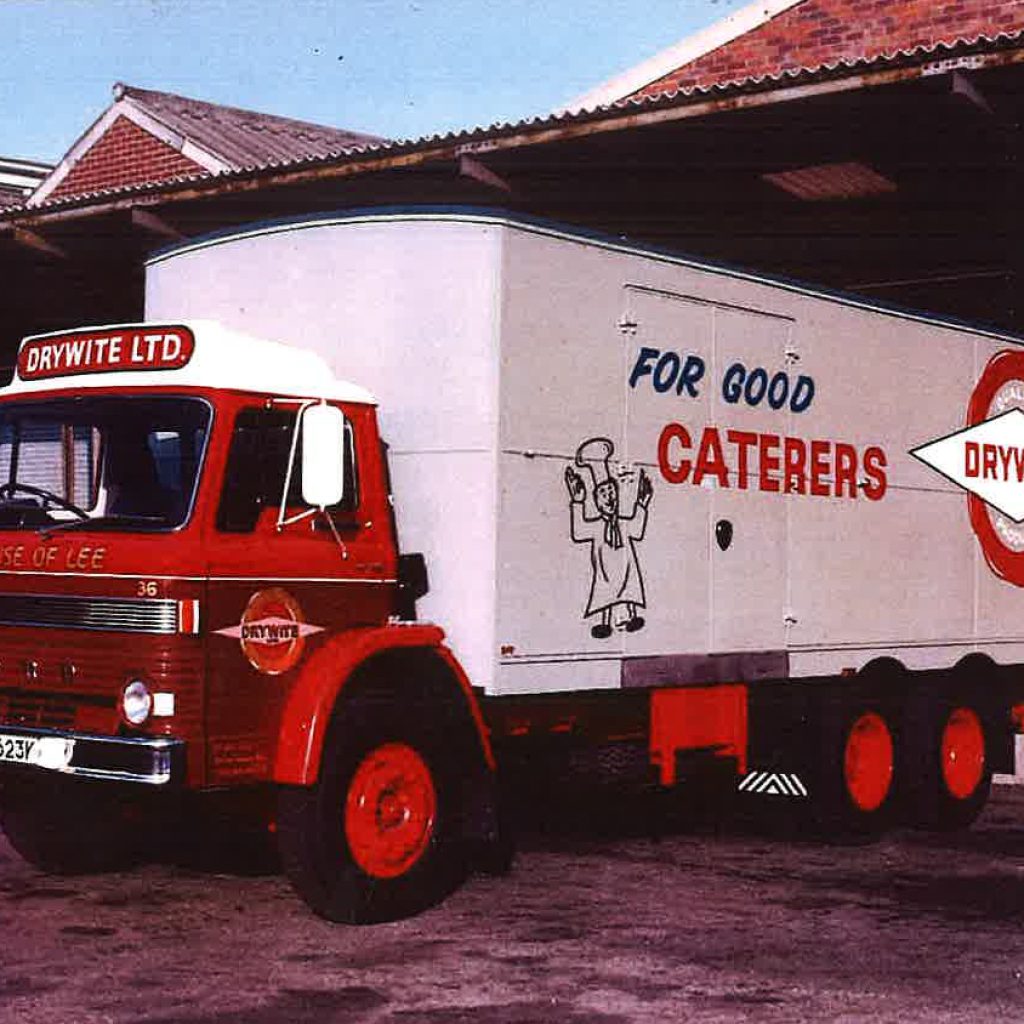

Patented as Drywite Potato Preparation, the business changed its name and Drywite was formed. Drywite Potato Preparation is still used today by fish and chip shops, as well as foodservice operators and vegetable processors.

During its 90 years, Drywite has expanded; moving premises to its current Park Lane factory in Halesowen; growing its product range to include preservatives, washes, detergents, utensils and equipment; and developing new markets such as overseas vegetable processing companies. Yet still, it has remained a thriving, family-owned business with a 30-strong loyal workforce and an eye for innovation.

Third-generation family member Kelvin Lee, who has served as managing director since 1988, comments: “We’re delighted to be celebrating 90 years in business. Fish and chips is a unique industry and there have been many mergers and acquisitions, which means it’s an achievement to stay in private ownership for so long. We have an amazing workforce that has remained loyal to us for many years, and we would not be here if it were not for them.”

Innovating

Describing the business as having its pressures due to the industry becoming more regulated, Kelvin attributes Drywite’s longevity to keeping up with legislation and trends, and innovating.

Kelvin recalls a conversation with his father, Malcom Lee. “I remember my father telling me how fish friers used to wash their potatoes in wooden barrels,” he says. “One day, he came across a company molding polythene tubs for washing babies and he thought that’s a good idea for washing chips. For a mold to be produced, he needed to commit to buying 10,000 so he bit the bullet, got the mold made and produced a hygienic polythene chip bin. The local authorities all thought it was fantastic and shops still use it today!”

Proud of everything his family has achieved, Kelvin likes to look forward as much as he does back at his family history and says: “The fish and chip industry has its ups and downs, but it’s a great industry with a great future and we are delighted to be part of that.

Loyal workforce

Drywite describes itself as being fortunate because it has always had a remarkably loyal and dedicated workforce. Many staff members over the years have completed 40 or more years of service and, even today, 10 of its 30 staff have over 25 years under their belts.

One of those longstanding employees is Nigel Perry, who started as a warehouse assistant and van driver when he was just 20. Fourty years on, Nigel is still with the company as stores and distribution manager. What’s more, both his mother and father worked at Drywite, which means there has been a member of the Perry family working for the company the entire 60 years it has been in Park Lane. Nigel recalls: ”My dad didn’t tell my mum he was going for the interview so when he got the job my mum turned up for work and got quite the surprise!”

Explaining why he and so many have stayed at Drywite, Nigel says it’s the people and the way they are looked after by the company, adding: “It’s a nice family firm to work for, the people are fantastic and many have turned out to be good friends.”

Having witnessed a huge number of changes in his time, Nigel says the most significant development was the move over to computers, making communications quicker and the transport of goods around the country more efficient and easier to track. He adds: “The other big change has been automation. When I started, everything was filled by hand and eye, you turned a tap on and stopped it when a bottle was full. Now it’s fully automated machinery, so it’s a lot quicker!”

Drywite 01384 569556 www.drywite.co.uk